NAVCO Railside Railcar Shaker

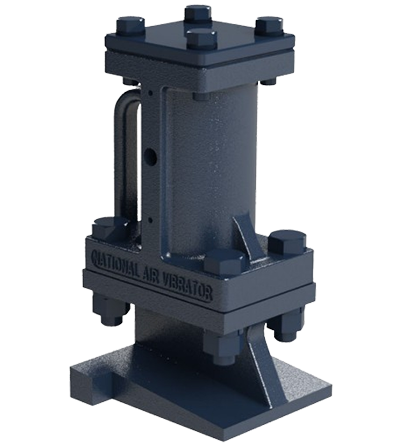

Railside Railcar Shaker – Built for Heavy-Duty Railcar Unloading

The Railside Railcar Shaker is designed for industries that handle tough, compacted, or moisture-laden bulk materials. Engineered with a high-amplitude, low-frequency vibration system, it effectively breaks rat-holes, reduces bridging, and promotes consistent material flow during railcar unloading.

Built Tough for the Harshest Applications

Manufactured in the USA, this railcar shaker features rugged steel construction and minimal moving parts—delivering years of reliable performance with low maintenance requirements. It is specifically designed for continuous use in industrial environments where downtime is not an option.

Suitable for a Wide Range of Industries

The Railside Railcar Shaker is trusted by industries including:

-

Aggregates & Mining

-

Chemical & Refining

-

Grain & Feed

-

Cement

-

Power Plants

-

Fertilizers

-

Bulk Material Processing

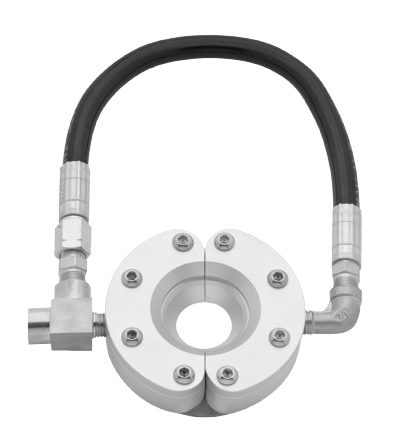

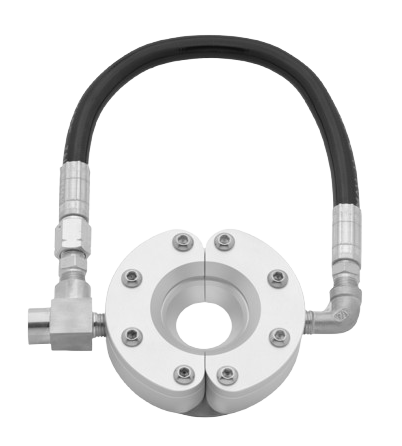

Pneumatic & Electric Drive Options

Available in both pneumatic and electric models, the shaker can be easily integrated into existing railcar unloading systems, offering flexibility and ease of installation.

Faster, Safer, and More Efficient Railcar Unloading

By automating the vibration process, the system eliminates the need for manual pounding or scraping inside railcars. Operators remain safe while unloading times are drastically reduced.

Optimized for Loading Efficiency

During loading, the shaker enhances:

-

Geometric alignment of particles

-

Reduction of angle of repose

-

De-aeration of materials

This ensures that each railcar achieves its maximum payload capacity, reducing transportation costs.

Increases Throughput & Lowers Operating Cost

With faster unloading, increased load density, and reduced manual labor, the Railside Railcar Shaker enhances productivity and lowers overall material handling costs for plants of any size.