Airmasters Air Knife Extra Manufacturers in Maharashtra, India.

ACE Flow Konzepts Pvt Ltd is a leading Airmasters Air Knife Extra Manufacturer and Supplier in Maharashtra, offering high-performance and durable air knives designed for efficient drying, cooling, and cleaning applications across diverse industrial sectors in India.

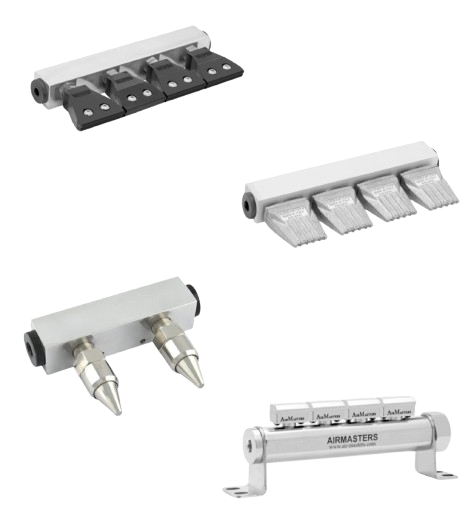

Our Airmasters Air Knife Extra Series is engineered to deliver powerful, precise, and controlled airflow while reducing compressed air consumption and noise levels. Manufactured in hard anodized aluminium or stainless steel 304 / 316L, these air knives ensure long service life, high strength, and corrosion resistance, even in the most demanding industrial environments.

Compact, robust, and maintenance-free, the Air Knife Extra Series is ideal for continuous industrial operations where reliability, performance, and efficiency are critical.

Working Principle

The Airmasters Air Knife Extra replaces traditional drilled or perforated pipes by directing compressed air through a series of precision-engineered nozzles.

These nozzles accelerate and amplify the airflow, producing a uniform, high-velocity air stream across the entire length of the knife.

The blowing force is controlled by the thickness of internal stainless-steel shims, allowing users to adjust air consumption, sound level, and airflow as per their application. The easy-to-open nozzle design allows simple cleaning and maintenance, ensuring consistent performance without clogging.

Key Features

-

Available with 2, 3, 4, or 6 nozzles

-

Constructed from hard anodized aluminium or stainless steel 304 / 316L

-

Adjustable blowing force using internal stainless-steel shims

-

Low noise and low air consumption — replaces drilled pipes efficiently

-

High resistance to mechanical wear and impact

-

Complies with OSHA regulations for safety and performance

-

Easy cleaning and maintenance with openable nozzle design

-

Standard nozzle gap: 0.28”

-

Custom sizes and configurations available at no additional cost

Applications

-

Drying and cooling components, molds, or parts

-

Removing dust, water, and debris from surfaces

-

Air curtain creation in conveyor and packaging systems

-

Cleaning before coating or painting processes

-

Suitable for automotive, electronics, printing, food, and packaging industries

-

Replacing inefficient and noisy air blowers or pipes

Advantages

-

Energy-efficient operation with reduced compressed air usage

-

Uniform and precise airflow for consistent results

-

Quiet, safe, and maintenance-free performance

-

No moving parts, ensuring long-term reliability

-

Corrosion- and impact-resistant materials for durability

-

Easy installation and integration into existing systems

-

Custom designs available without extra cost

-

Environmentally friendly, using only compressed air

Airmasters Air Knife Extra in India

ACE Flow Konzepts Pvt Ltd is recognized among the top Airmasters Air Knife Extra Suppliers in India, providing reliable, efficient, and customizable air-blowing solutions for industrial drying, cleaning, and cooling needs.

Our Air Knife Extra Series combines advanced airflow technology, robust construction, and energy-efficient design, ensuring optimal performance, reduced noise, and significant operational cost savings.

Whether your goal is to cool, dry, or clean, the Airmasters Air Knife Extra delivers unmatched precision, durability, and performance in every industrial environment.

| Model | Material | Blowing force at 5 Bar / 72.5 PSI | Air consumption at 5 bar / 72.5 PSI | Air Amplification | Sound level at 5 Bar / 72.5 PSI | Shims | Dimensions | Connection type | Back connection | Side connections | Blowing pattern | Max operating pressure |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AIR-ZPE236 | Zinc | 28.06 OZ | 42 Nm³/h / 26.14 SCFM | 71 dB(A) | 83 mm x 70 mm x 23 mm | Female | 3/8" x 1 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | ||

| AIR-ZPE436 | Zinc | 15.6 N | 84 Nm³/h / 52.34 SCFM | 74 dB(A) | 164 mm x 70 mm x 23 mm | Female | 3/8" x 1 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | ||

| AIR-ZPE636 | Zinc | 23.4 N | 126 Nm³/h / 78.5 SCFM | 77 dB(A) | 244 mm x 70 mm x 23 mm | Female | 3/8" x 1 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | ||

| AIR-ZPE246 | Zinc | 11.4 N | 54 Nm³/h / 33.61 SCFM | 74.5 dB(A) | 105 mm x 77 mm x 23 mm | Female | 3/8" x 1 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | ||

| AIR-ZPE346 | Zinc | 6.11 OZ | 81 Nm³/h / 50.47 SCFM | 76 dB(A) | 156 mm x 77 mm x 23 mm | Female | 3/8" x 1 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | ||

| AIR-ZPE446 | Zinc | 22.5 N | 108 Nm³/h / 67.29 SCFM | 78 dB(A) | 207 mm x 77 mm x 23 mm | Female | 3/8" x 1 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | ||

| AIR-ZPE646 | Zinc | 118.7 OZ | 150 Nm³/h / 93.46 SCFM | 81 dB(A) | 310 mm x 77 mm x 23 mm | Female | 3/8" x 1 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | ||

| AIR-ZPE274 | Zinc | 22 N | 82 Nm³/h / 51.09 SCFM | 75 dB(A) | 157 mm x 95 mm x 25 mm | Female | 3/8" x 2 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | ||

| AIR-ZPE374 | Zinc | 118.7 OZ | 123 Nm³/h / 76.64 SCFM | 78 dB(A) | 243 mm x 95 mm x 25 mm | Female | 3/8" x 2 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | ||

| AIR-ZPE474 | Zinc | 44 N | 164 Nm³/h / 102.18 SCFM | 82 dB(A) | 311 mm x 95 mm x 25 mm | Female | 3/8" x 2 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | ||

| AIR-ZPE674 | Zinc | 55 N | 246 Nm³/h / 153.27 SCFM | 86 dB(A) | 465 mm x 95 mm x 25 mm | Female | 3/8" x 2 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | ||

| SL02 | Aluminum, Stainless steel 316L | 25.18 OZ | 39 Nm³/h / 24.27 SCFM | 84 dB(A) | 80 mm x 40 mm x 25 mm | Female | 3/8" x 1 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | ||

| SL04 | Aluminum, Stainless steel 316L | 50.36 OZ | 78 Nm³/h / 48.54 SCFM | 86.5 dB(A) | 140 mm x 40 mm x 25 mm | Female | 3/8" x 1 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | ||

| SL06 | Aluminum, Stainless steel 316L | 75.54 OZ | 117 Nm³/h / 72.81 SCFM | 89 dB(A) | 200 mm x 40 mm x 25 mm | Female | 3/8" x 2 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | ||

| GM02 | Hardened anodized aluminum | 41.72 OZ, 57.55 OZ, 77.33 OZ | 58 Nm³/h – 108 Nm³/h – 115 Nm³/h | 82 dB(A) | Stainless steel | 100 mm x 82 mm x 25 mm | Female | 3/8" x 1 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | |

| GM03 | Hardened anodized aluminum | 61.15 OZ, 86.33 OZ, 118.7 OZ | 87 Nm³/h, 162 Nm³/h, 172 Nm³/h | 85 dB(A) | Stainless steel | 162 mm x 82 mm x 25 mm | Female | 3/8" x 1 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | |

| GM04 | Hardened anodized aluminum | 83.45 OZ, 115.1 OZ, 154.67 OZ | 116 Nm³/h – 216 Nm³/h – 230 Nm³/h | 85 dB(A) | Stainless steel | 204 mm x 82 mm x 25 mm | Female | 3/8" x 1 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | |

| GM06 | Hardened anodized aluminum | 125.17 OZ, 172.65 OZ, 232 OZ | 174 Nm³/h – 324 Nm³/h – 345 Nm³/h | 89 dB(A) | Stainless steel | 306 mm x 82 mm x 25 mm | Female | 1/2" x 1 | 1/2" x 1 | Flat | 10 Bar / 145 PSI | |

| GM02S | Stainless steel | 41.72 OZ, 57.55 OZ, 77.33 OZ | 58 Nm³/h – 108 Nm³/h – 115 Nm³/h | 82 dB(A) | Stainless steel | 100 mm x 82 mm x 25 mm | Female | 3/8" x 1 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | |

| GM03S | Stainless steel | 61.15 OZ, 86.33 OZ, 118.7 OZ | 87 Nm³/h, 162 Nm³/h, 172 Nm³/h | 85 dB(A) | Stainless steel | 162 mm x 82 mm x 25 mm | Female | 3/8" x 1 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | |

| GM04S | Stainless steel | 83.45 OZ, 115.1 OZ, 154.67 OZ | 116 Nm³/h – 216 Nm³/h – 230 Nm³/h | 85 dB(A) | Stainless steel | 204 mm x 82 mm x 25 mm | Female | 3/8" x 1 | 3/8" x 2 | Flat | 10 Bar / 145 PSI | |

| GM06S | Stainless steel | 125.17 OZ, 172.65 OZ, 232 OZ | 174 Nm³/h – 324 Nm³/h – 345 Nm³/h | 89 dB(A) | Stainless steel | 306 mm x 82 mm x 25 mm | Female | 1/2" x 1 | 1/2" x 2 | Flat | 10 Bar / 145 PSI | |

| AIR-148S | Stainless steel 316L | 25.18 OZ | 39 Nm³/h / 24.27 SCFM | 84 dB(A) | 80 mm x 40 mm x 25 mm | Female | Flat | 10 Bar / 145 PSI | ||||

| AIR-149S | Stainless steel 316L | 50.36 OZ | 78 Nm³/h / 48.54 SCFM | 86.5 dB(A) | 140 mm x 40 mm x 25 mm | Female | Flat | 10 Bar / 145 PSI | ||||

| AIR-150S | Stainless steel 316L | 75.54 OZ | 117 Nm³/h / 72.81 SCFM | 89 dB(A) | 200 mm x 40 mm x 25 mm | Female | Flat | 10 Bar / 145 PSI | ||||

| LR02 | 1.6 lbs | 35 Nm³/h / 21.78 SCFM | 35:1 | 79 dB(A) | 100 mm x 75 mm x 25 mm | Female | 3/8" x 1 | 3/8" x 2 | Round | 10 Bar / 145 PSI | ||

| LR03 | 22.5 N | 51 Nm³/h / 31.74 SCFM | 35:1 | 78 dB(A) | 163 mm x 75 mm x 31.8 mm | Female | 3/8" x 1 | 3/8" x 2 | Round | 10 Bar / 145 PSI | ||

| LR04 | 53.95 OZ | 69 Nm³/h / 42.94 SCFM | 35:1 | 81 dB(A) | 204 mm x 75 mm x 25 mm | Female | 3/8" x 1 | 3/8" x 2 | Round | 10 Bar / 145 PSI | ||

| LR06 | 22.5 N | 101 Nm³/h / 62.85 SCFM | 35:1 | 84 dB(A) | 306 mm x 75 mm x 25 mm | Female | 3/4" x 1 | 3/4" x 2 | Round | 10 Bar / 145 PSI | ||

| LR02SS | 1.6 lbs | 35 Nm³/h / 21.78 SCFM | 35:1 | 79 dB(A) | 100 mm x 75 mm x 25 mm | Female | 3/8" x 1 | 3/8" x 2 | Round | 10 Bar / 145 PSI | ||

| LR03SS | 22.5 N | 51 Nm³/h / 31.74 SCFM | 35:1 | 78 dB(A) | 163 mm x 75 mm x 31.8 mm | Female | 3/8" x 1 | 3/8" x 2 | Round | 10 Bar / 145 PSI | ||

| LR04SS | 53.95 OZ | 69 Nm³/h / 42.94 SCFM | 35:1 | 81 dB(A) | 204 mm x 75 mm x 25 mm | Female | 3/4" x 1 | 3/4" x 2 | Round | 10 Bar / 145 PSI | ||

| LR06SS | 22.5 N | 101 Nm³/h / 62.85 SCFM | 35:1 | 84 dB(A) | 306 mm x 75 mm x 25 mm | Female | 3/4" x 1 | 3/4" x 2 | Round | 10 Bar / 145 PSI | ||

| LR02S-316L | 1.6 lbs | 35 Nm³/h / 21.78 SCFM | 35:1 | 79 dB(A) | 100 mm x 75 mm x 25 mm | Female | 3/8" x 1 | 3/8" x 2 | Round | 10 Bar / 145 PSI | ||

| LR03S-316L | 22.5 N | 51 Nm³/h / 31.74 SCFM | 35:1 | 78 dB(A) | 163 mm x 75 mm x 31.8 mm | Female | 3/8" x 1 | 3/8" x 2 | Round | 10 Bar / 145 PSI | ||

| LR04S-316L | 53.95 OZ | 69 Nm³/h / 42.94 SCFM | 35:1 | 81 dB(A) | 204 mm x 75 mm x 25 mm | Female | 3/4" x 1 | 3/4" x 2 | Round | 10 Bar / 145 PSI | ||

| LR06-316L | 22.5 N | 101 Nm³/h / 62.85 SCFM | 35:1 | 84 dB(A) | 306 mm x 75 mm x 25 mm | Female | 3/4" x 1 | 3/4" x 2 | Round | 10 Bar / 145 PSI | ||

| TS02 | Stainless steel | 40 OZ | 57 Nm³/h / 35.47 SCFM | 87 dB(A) | 162 mm x 95 mm x 31 mm | Female | 1/2" x 2 | 1/2" x 2 | Flat | 10 Bar / 145 PSI | ||

| TS03 | Stainless steel | 57.55 OZ | 88 Nm³/h / 54.76 SCFM | 87 dB(A) | 162 mm x 95 mm x 31 mm | Female | 1/2" x 2 | 1/2" x 2 | Flat | 10 Bar / 145 PSI | ||

| TS04 | Stainless steel | 77.33 OZ | 116 Nm³/h / 72.18 SCFM | 88 dB(A) | 204 mm x 95 mm x 31 mm | Female | 1/2" x 2 | 1/2" x 2 | Flat | 10 Bar / 145 PSI | ||

| TS06 | Stainless steel | 118.7 OZ | 174 Nm³/h / 108.27 SCFM | 90 dB(A) | 306 mm x 95 mm x 31 mm | Female | 1/2" x 2 | 1/2" x 2 | Flat | 10 Bar / 145 PSI |